Grollmus

Learning and working in the future of engineering

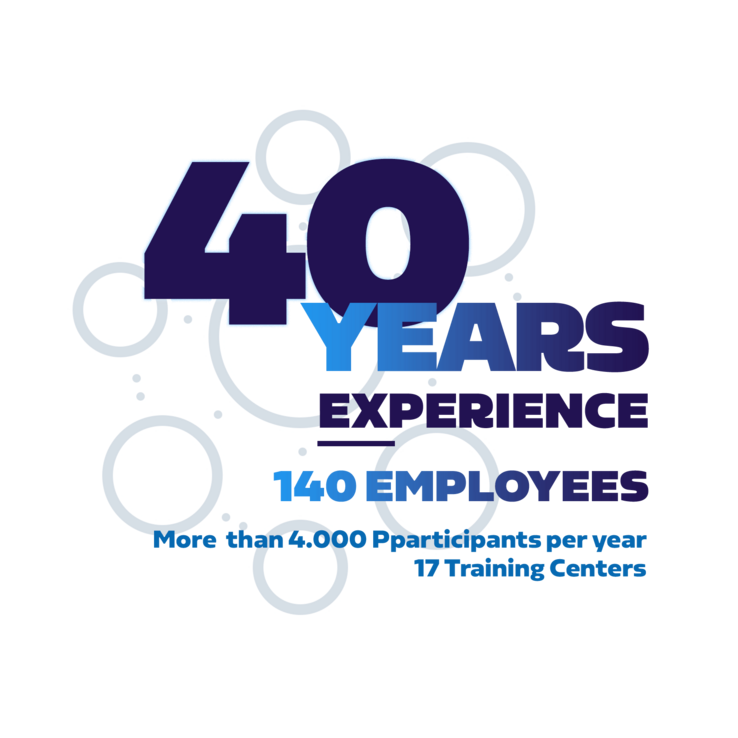

Grollmus has more than 40 years of know-how in the training and project planning of systems for automation, drive technology and IT. In addition, our top-qualified software team develops individual solutions for programming and configuring automated systems.

Training courses

At 17 locations in Germany, Austria and Switzerland, as well as online, we train in both German and English. Every year, we turn more than 4,000 participants into experts. Our systematic training concept brings participants to a new level of knowledge. At the same time, it ensures that learning is fun and enthusiastic. We specialise in control technology from Siemens and Beckhoff. We also conduct all training courses as in-house training at our customers' premises. We bring all equipment and documentation and provide individual training, tailored to their needs. We specialise in control technology from Siemens and Beckhoff. We also run all training courses as in-house training at our customers' premises. We equip them with all equipment and documentation and provide individual training, tailored to their needs.

Software for automation technology

We develop innovative software solutions for programming and configuring automated systems. In doing so, we use cutting-edge technologies and exploit the advantages of agile frameworks. This enables us to implement customised software solutions. As a partner of Siemens and Microsoft, we have excellent prospects for the future. Agile development processes according to Scrum and the close coordination of product owners with our customers ensure optimal results.

TIA Selection Tool

Since 2011, we have been developing the TIA Selection Tool for SIEMENS - a configurator and ordering system for devices in the field of control and drive technology. With more than 90,000 users per month, the TIA Selection Tool is the most-used Siemens Industry configurator and is in use worldwide in 7 languages - both as a desktop application and via the browser as a web application.

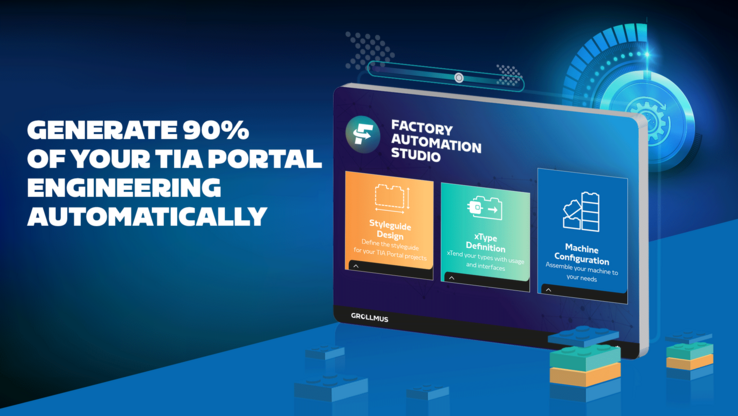

Factory Automation Studio

Our Factory Automation Studio forms the heart of the standardisation process and is the control centre of the digital workflow. This software leads to enormous increases in efficiency for all participants in the engineering process with the TIA Portal: From electrical design and PLC programming to commissioning and ongoing operation!

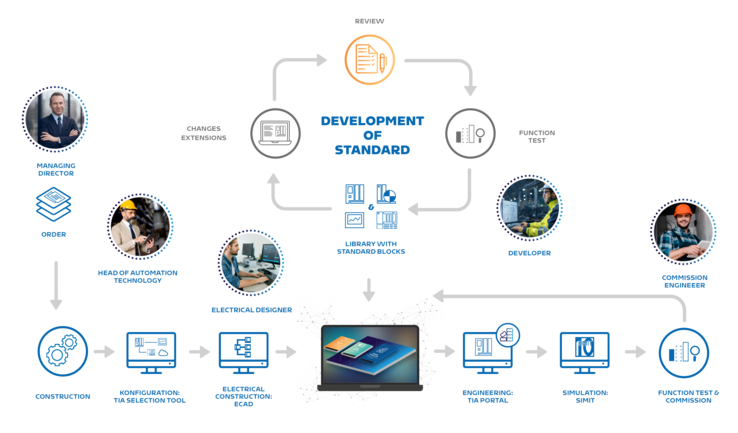

Digital workflow

The standardisation of the engineering process and the implementation of a digital workflow lead to faster development times and a seamless linking of the individual work steps. Everyone involved benefits from this. Our automation experts analyse the current situation of our customers and help them to implement a continuous digital workflow, regardless of whether they are at the beginning of the introduction of standards or are already well advanced.

Connector

Factory Automation Studio – EPLAN integration

Factory Automation Studio automatically generates the PLC software in TIA Portal in three steps. In the first step, the project structure is imported from EPLAN. Here, those plants and locations of the electrical circuit diagram are selected for which groups, program blocks and data blocks are to be generated automatically. The PLC program is then created. The appropriate blocks from TIA Portal library are used for this. These are automatically called up and connected by Factory Automation Studio for the respective project. The third step consists of the automatic generation of the TIA Portal project. Factory Automation Studio creates the pre-selected structure from the electrical diagram including blocks and block calls in TIA Portal without a single manual input.