Automated panel production:

From the digital twin to the finished control cabinet in record time

There’s no need to worry about a lack of skilled personnel for control panel manufacturing: with EPLAN software and perfectly matched manufacturing equipment from Rittal, you can effectively save working hours and resources. Use qualified personnel in a more targeted manner, while less-experienced workers can quickly produce control cabinets.

Let's focus on the wiring of your control panels. Efficiencies in Level 0, 1 and 2 provides you with the ability to calculate the length of your wires. That information opens the possibility of splitting the wiring process into two separate tasks and automatically increase your productivity. Find out how.

Are you ready to follow the Path to Efficiency?

Let’s take this journey together!

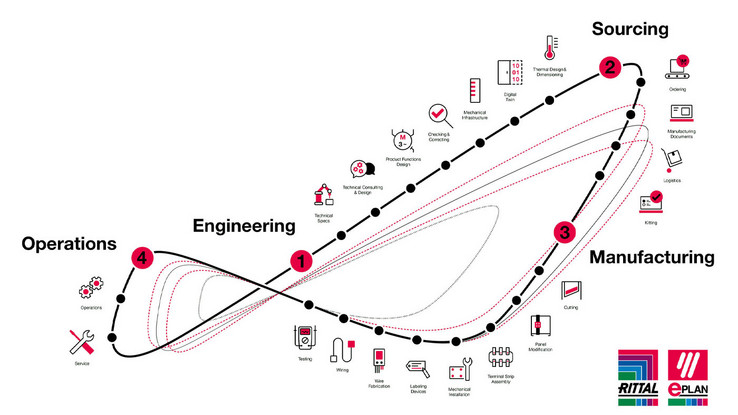

EPLAN Performance Integrator

Routing & Automation

The company takes advantage of a reorganized production workflow for the manufacturing phase by calculating wire lengths, pre-fabricating wires and using the Rittal Application Centre or automation equipment.

Reorganized workflow

Today, the panel building workflow requires us to work in sequence. This means that we need to wait for the mechanical assembly to be to be fully completed before we can start the wiring of the panel.

But, if your design department plans the layout of their control cabinets in 3D and takes advantage of the Digital Twin, the data from the engineering designs can serve as the technical specifications for the production. For instance, mounting plates can be drilled fully automatically, or cables routed in 3D can be cut-to-length and crimped.

When this happens, you are free to transform your workflow from a sequential process to a parallel process. When you know the length of your wires, you can separate the tasks of fabricating and landing your wires. It becomes possible to start the wire fabrication at the beginning of your manufacturing phase, in parallel with the asssembly. This is possible with EPLAN Smart Wiring and the results are substantial savings that allow you to deliver your projects earlier.

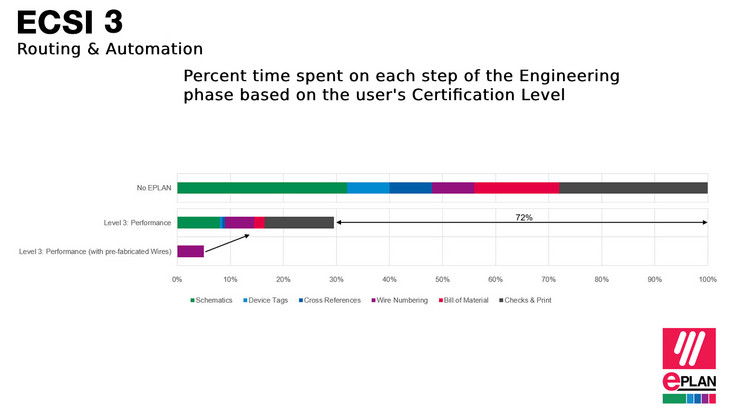

With Level 3, there are no substantial gains for engineering when compared to previous levels. The additional benefits are on the manufacturing side, when time gets reinvested into wire numbering documentation.

- All the savings from Level 0, Level 1 and Level 2

- By investing a little more time on the documentation surrounding your wire numbering, you can have EPLAN help calculate the length of your wires.

Time spent in the wire numbering goes up from 1% to 5% - With this information, wires can be pre-fabricated which leads to a 33% reduction on your projects delivery time on the Manufacturing side.

Total savings 72%

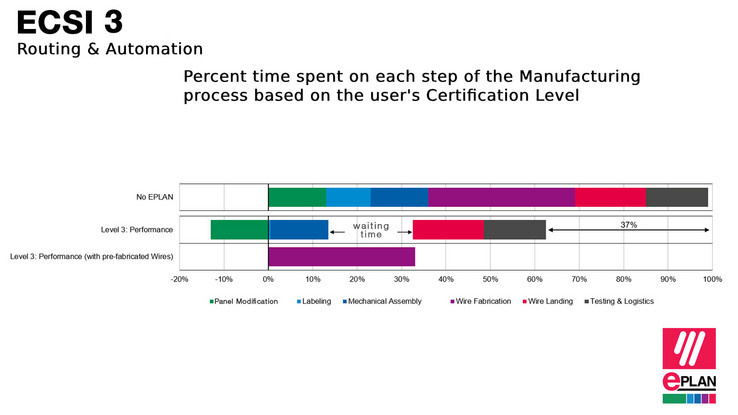

In Level 3, efficiency is achieved by reorganizing production workflows. We focus on the wiring step of the manufacturing process because it is the most time-consuming task. Thanks to the benefits gained from using EPLAN in the earlier Levels, you end up with the ability to calculate the length of your wires before manufacturing.

This also means that you can separate the tasks of wire fabrication and wire landing. Furthermore, using EPLAN Smart Wiring the task can be done them in parallel by anyone with access to your project.

- All the savings from Level 0, Level 1 and Level 2

- Knowing the length of the wires lets you separate the job requiring less technical skills (fabrication) and the job requiring technical skill (landing)

- Larger pool of resources

- Wiring can start earlier. No need to wait for full assembly

Total savings 37%

More information on Routing and Automation

Efficient Routing

Benefits or Wire Routing

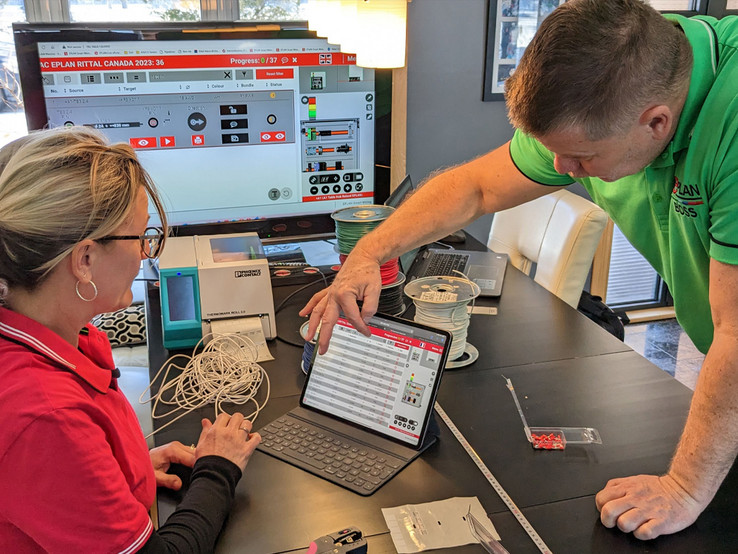

EPLAN expert Roland Younk presents Smart Wiring and and wire routing in EPLAN Pro Panel

Study on Efficient Panel Building

Control Cabinet Engineering 4.0

A study by University of Stuttgart on the potential of automation and digitalization in panel building

Rittal Automation System

RAS and Mod Center

Building panels using Rittal fully automated machine technology and the Mod Center

Become an EPLAN Certified Systems Integrator

By virtue of obtaining its EPLAN Certification, your company signals to the world that it possess highly sought expertise in the industry and that it adheres to a set of best practices in electrical engineering, panel building and automation.

Reach out to your EPLAN representative to learn more about the requirements for the EPLAN certification.