Small changes, big impacts:

Standardisation for fast electrical engineering designs

The EPLAN Certified Systems Integrator Program - ECSI 0123

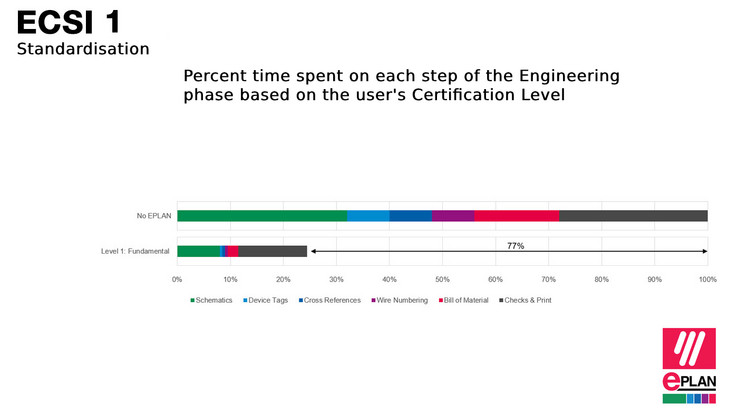

From setting standard guidelines for the company to creating teamplates for projects, optimization absolutely requires standardisation in engineering. The goal of our Level 1 certification is to ensure that your company fully benefits from the standardisation of their processes.

Are you ready to follow the Path to Efficiency?

Let’s take this journey together!

EPLAN Fundamental Integrator

Standardisation

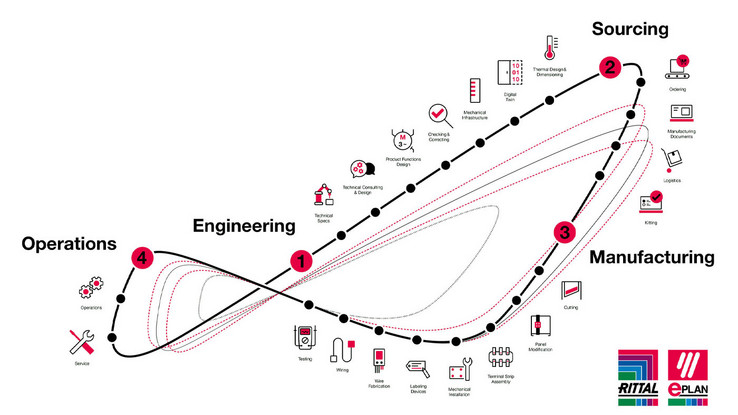

The company demonstrates fundamental knowledge of the EPLAN platform and shows a commitment to the standardisation of its process for design and production, which leads to the ability to automate the preparation of wire labels. The EPLAN platform allows them to create basic templates and reports that carry through the later stages of the Rittal-EPLAN Value Chain

Schematics are done faster than ever before with the help of those EPLAN tricks: using templates, creating macros, taking advantage of the Data Portal and more. In fact, EPLAN gives you access to over 1.4 million data sets, from over 440 manufacturers. This eliminates the need to create new parts for projects and speeds up the design process. Standardisation really is the magic word for exploiting EPLAN’s full potential.

The company focuses on the standardization of its process for design and production. EPLAN allows them to create basic templates and reports that carry through the later stages of the value chain such as plot frames, macros, labeling files, wire lists, BOMs, and more.

There are over 1.4 million data sets in the EPLAN Data Portal. In addition, the introduction of the EPLAN Cloud allows for better collaboration on projects, speeds up the revision process and eliminates the need for sharing and printing PDF.

- All the savings from Level 0

- Time spent creating schematics falls from 32% to 8%

- Time spent building a Bill of Material is further reduced from 16% to 2%

- Checks, revision and document printing is reduced from 28% to 13%

Total savings 77%

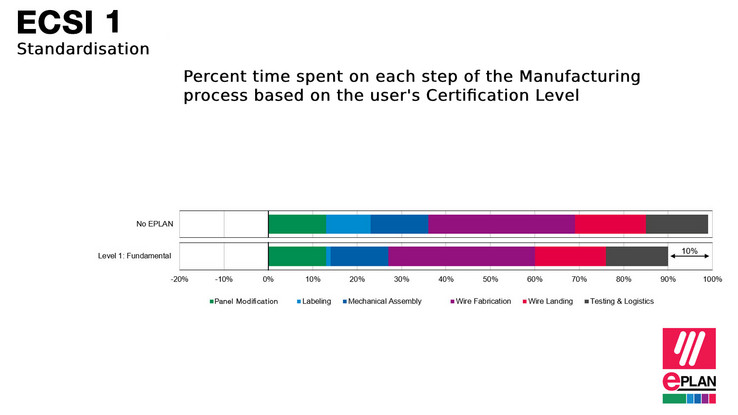

In Level 1, labeling is done automatically during the engineering phase, which leads to time saving for that task.

- Time spent creating and sorting labels is reduced from 10% to < 1%

Total savings 10%

More information on EPLAN Standardisation

Exporting Reports

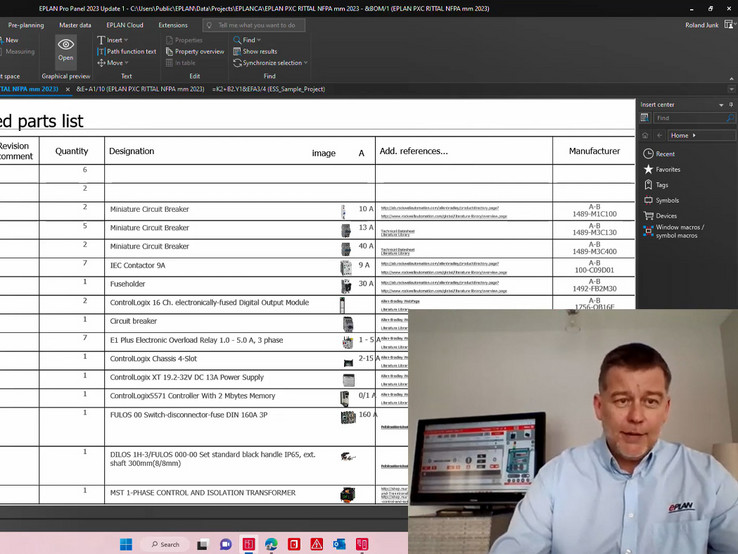

Exporting summarized parts lists

EPLAN expert Roland Younk explains how labeling data and bill of material can be exported to Excel or your ERP.

The EPLAN Data Portal

High-Quality Component Data

An extensive catalogue of parts data with information straigth from manufacturers

Become an EPLAN Certified Systems Integrator

By virtue of obtaining its EPLAN Certification, your company signals to the world that it possess highly sought expertise in the industry and that it adheres to a set of best practices in electrical engineering, panel building and automation.

Reach out to your EPLAN representative to learn more about the requirements for the EPLAN certification.