Panel designs in 3D:

How the digital twin simplifies your control cabinet designs and production

The EPLAN Certified Systems Integrator Program - ECSI 0123

The company demonstrates advanced knowledge of the EPLAN platform and utilizes features possible when 3D design is used and the Digital Twin is introduced into their workflow. With standardised schematic creation as a foundation, control cabinet designs in 3D are also in reach for your company.

When you reach Level 2, 3D project and the Digital Twin allows you to troubleshoot for potential errors and catch them at the engineering phase.

Are you ready to follow the Path to Efficiency?

Let’s take this journey together!

EPLAN Advanced Integrator

Digital Twin

The company demonstrates advanced knowledge of the EPLAN platform and utilizes features enabled through the usage of the 3D digital twin into their workflow. While two-dimensional schematics can naturally be used to equip and cable control cabinets, some of the needed information is still missing.

The Digital Twin lets you do collision checks and take into account the accessories required to complete the panel (rain canopy, logs, cable ducts, lighting, climate control, fan, filters, and more.)

The Digital Twin can be shared with EPLAN eVIEW on the EPLAN Cloud.

Rittal Application Center

In addition, If you can produce the cutting and drilling information, then your panels can be pre-fabricated by the Rittal Application Center and arrive at your workshop premade, ready for the assembly and wiring.

A factor of 10X

One of the most compelling reason to push for the Digital Twin is the factor of 10X. In general, when using data from the schematics created in EPLAN, the gains made in engineering by Level 0 and Level 1 certified integrators can payoff even more in Manufacturing. In fact, every dollar saved on the engineering phase is able to save you around 10$ on the manufacturing side.

2D schematics vs 3D designs: comparing panel production

There definitely is! Using data from the schematics created in EPLAN, you can firstly compile important information for materials procurement. Secondly, the EPLAN project data is the perfect foundation for deriving a realistic digital twin of the planned control cabinet. The right 3D software makes it easier for electrical engineers when designing the control panel and for technicians when producing it.

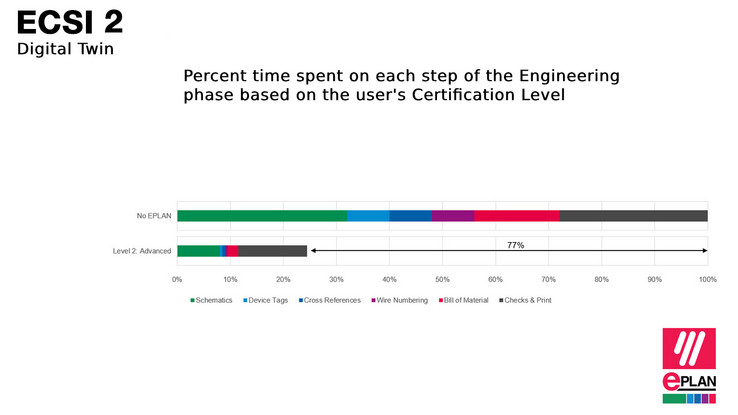

Percent time spent on each step of the Engineering phase based on the user's Certification Level

When you reach Level 2, the benefits come from working on a 3D project. You gain the Digital Twin, a digital representation of your project with accurate data, allowing you to troubleshoot for potential errors and catch them at the engineering phase.

In addition, the introduction of the EPLAN Cloud eliminates the need for PDF and speeds up the revision of projects by your team and customers.

Total savings 77%

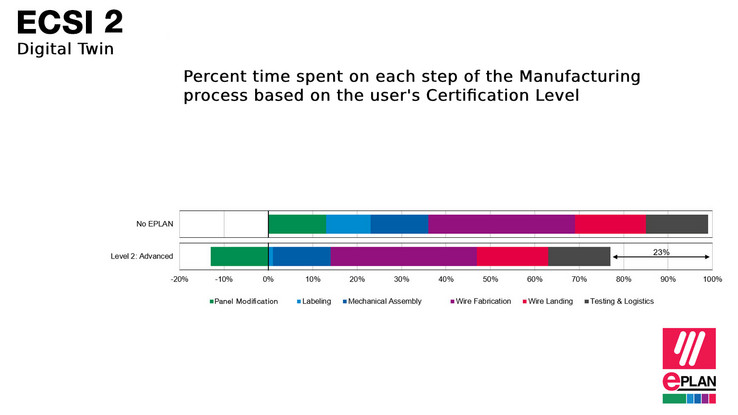

Percent time spent for each step of the manufacturing process based on the user's Certification Level

Before the actual panel assembly, drilling and cutting is required. When you take advantage of the Digital Twin, you produce accurate documentation on your project. You can opt to provide that documentation and the reports to the Rittal Mod Center and have your you panel arrive to the floor pre-drilled and pre-cut, ready for assembly and wiring.

This eliminates a step for you and allows you to start your manufacturing phase with the panel assembly.

- All the savings from Level 0, and Level 1

- Eliminate the time spent on the mechanical planning of your panel by sending it to the Rittal Mod Center. Your time spent for the Mechanical planning drops from 13% to 0%

Total savings 23%

More information on the Digital Twin

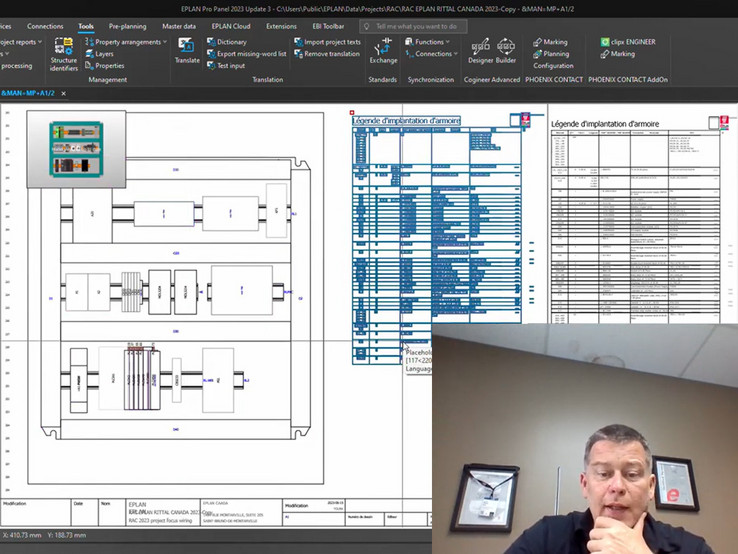

Digital Twin Englosure Legend

The versatility of Model View

Define how and what you want to see in your enclosure legend

EPLAN in the Industry

EPLAN in Practice

Take advantage of Digitalization's opportunity with EPLAN, no matter the industry

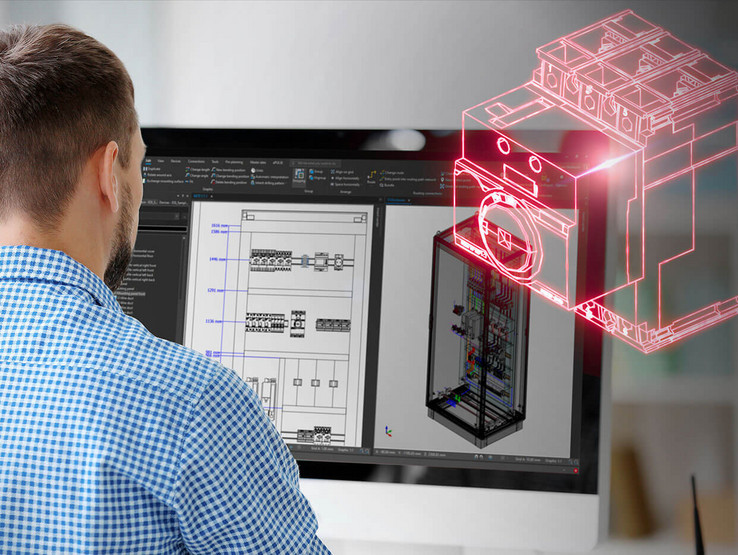

EPLAN Pro Panel

Designing in 3D

Integrated solution for automating and disutrialising your panel building and control cabinet design in 3D

Become an EPLAN Certified Systems Integrator

By virtue of obtaining its EPLAN Certification, your company signals to the world that it possess highly sought expertise in the industry and that it adheres to a set of best practices in electrical engineering, panel building and automation.

Reach out to your EPLAN representative to learn more about the requirements for the EPLAN certification.